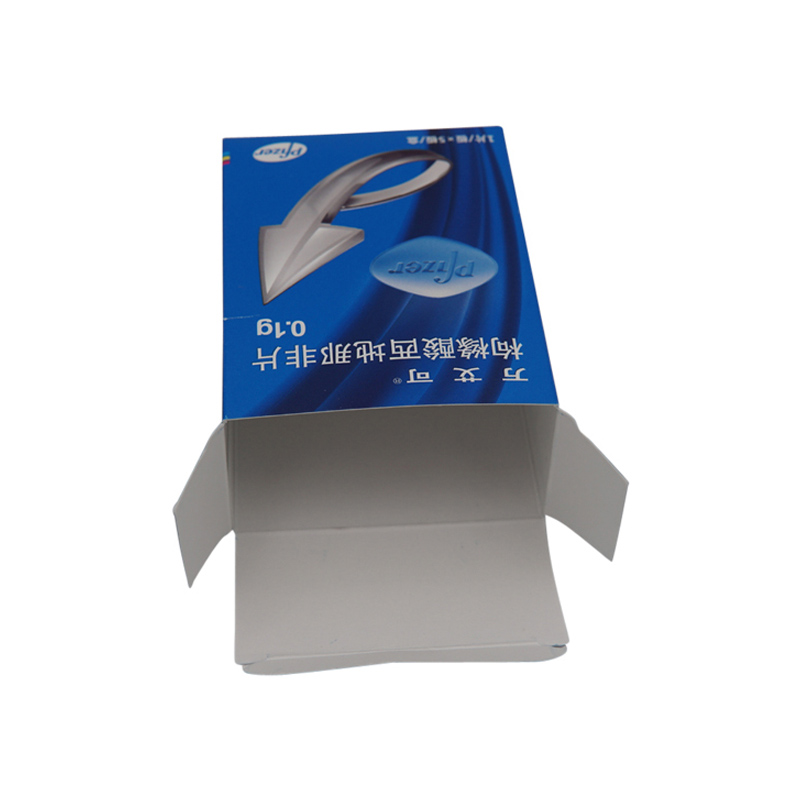

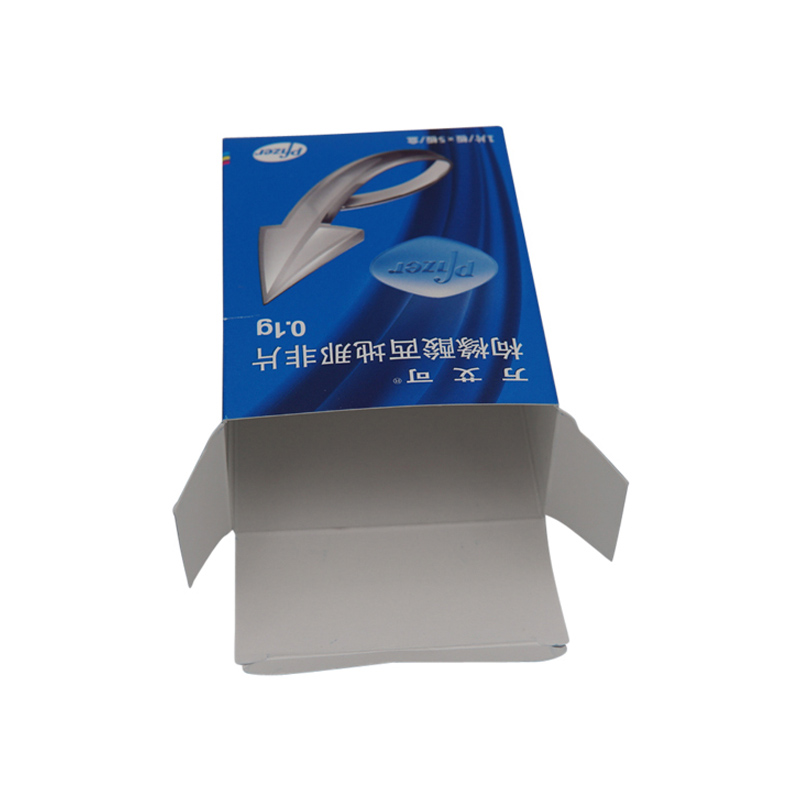

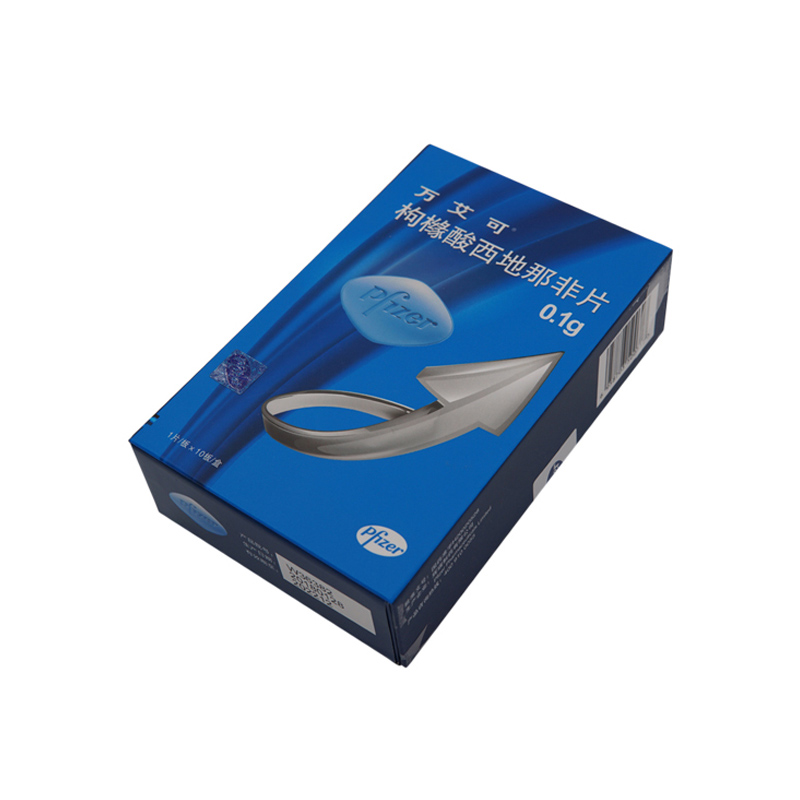

2.Medicine paper box is magnetic rigid box ,it's close very well and easy to open the paper box .The Box with matte laminate ourside .

3.Happy Packaging cooperate with several big medicine companies in the work and produce more than one million rigid box for midecine box every month .

In the pharmaceutical industry, packaging plays a critical role in ensuring the safety, integrity, and marketability of drugs. A customized

printing drug paper box is an essential component of pharmaceutical packaging, offering numerous benefits for both manufacturers and consumers. Today, I would like to introduce the advantages and features of customized printing for drug paper boxes.

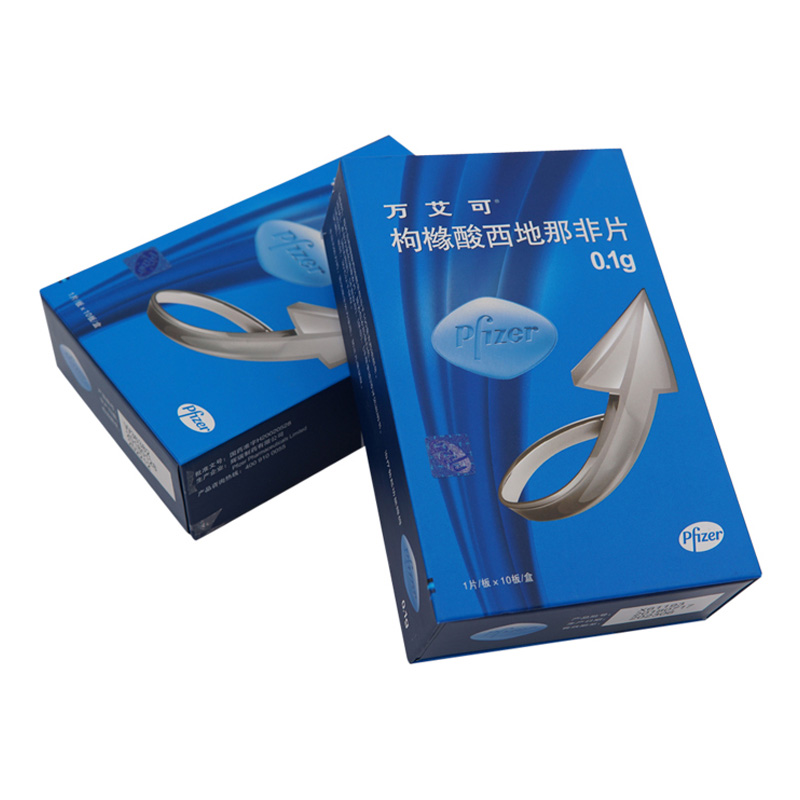

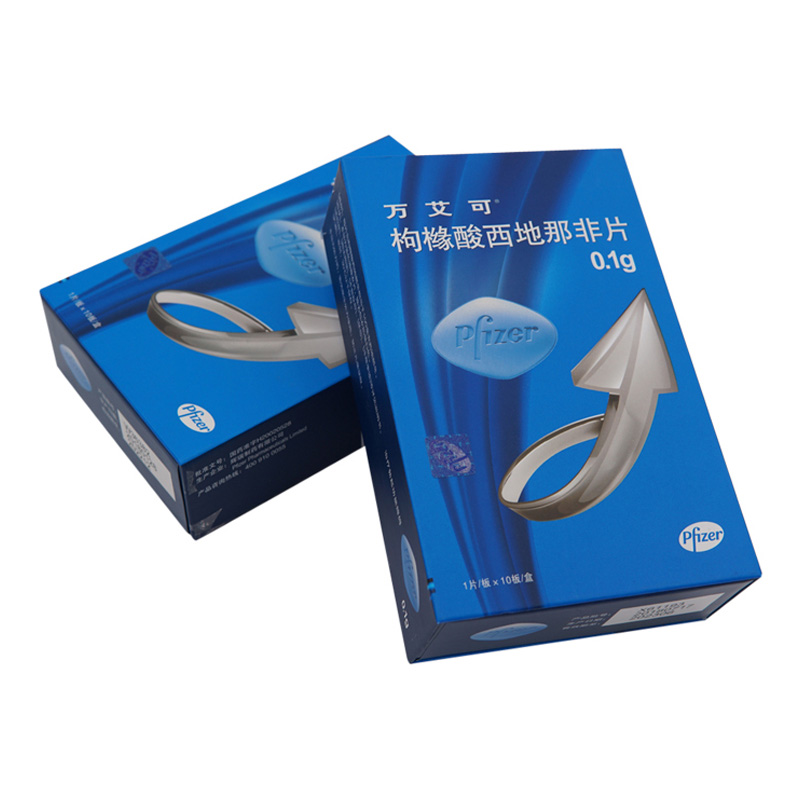

Firstly, customized printing allows pharmaceutical companies to create unique and visually appealing packaging designs. By incorporating their brand logo, colors, and relevant information, manufacturers can establish a strong brand identity and enhance brand recognition. This branding opportunity helps consumers easily identify the product and builds trust in its quality and authenticity.

Furthermore, customized printing on

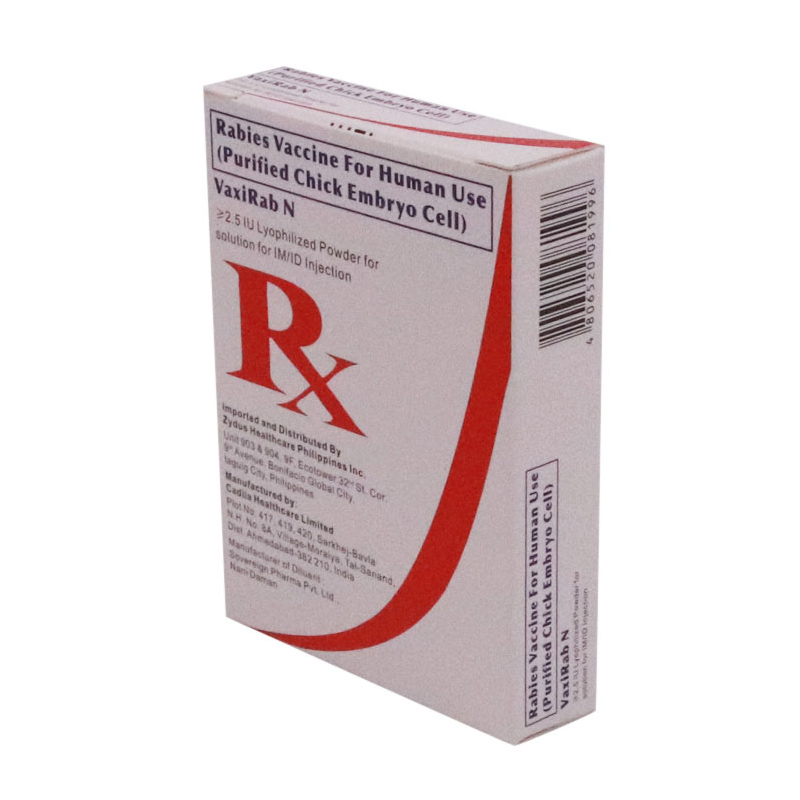

drug paper boxes allows for the inclusion of important product information. Dosage instructions, active ingredients, warnings, and usage guidelines can be prominently displayed, ensuring that consumers have all the necessary information at their fingertips. This not only promotes safe and responsible drug use but also helps to comply with regulatory requirements.

Additionally, customized printing offers flexibility in design and graphics. Pharmaceutical companies can choose from a wide range of colors, fonts, and imagery to create visually appealing and informative packaging. Eye-catching designs and graphics can attract consumer attention, differentiate the product from competitors, and contribute to increased sales.

Another advantage of customized printing is that it allows for serialization and track-and-trace capabilities. Unique identification codes, barcodes, or QR codes can be printed on the drug paper box, enabling effective tracking and monitoring of the product throughout the supply chain. This enhances product security, helps prevent counterfeiting, and ensures the authenticity of the medication.

Moreover, customized printing on

drug paper boxes can enhance product protection. The box can be designed to provide optimal protection against light, moisture, and other external factors that may affect the drug's stability and efficacy. By using high-quality materials and incorporating features such as tamper-evident seals, the packaging can ensure the integrity and safety of the drug during storage and transportation.

Lastly, customized printing can contribute to sustainability efforts. Manufacturers can choose eco-friendly materials for the

drug paper box, such as recyclable or biodegradable options, to reduce environmental impact. This aligns with the growing consumer demand for environmentally conscious products and demonstrates a commitment to sustainable packaging practices.

In conclusion, customized printing for drug paper boxes offers numerous advantages for pharmaceutical companies. It enables brand recognition, provides essential product information, enhances product protection, and supports sustainability efforts. By investing in customized printing, manufacturers can create packaging that not only meets regulatory requirements but also stands out in the market, ensuring the safe and effective delivery of medications to consumers.