Brief Analysis Of Three Printing Process Characteristics

Brief Analysis Of Three Printing Process Characteristics

custom shoe box with logo

Common carton printing processes include offset printing, flexo printing and gravure printing. Each of these three printing forms has its own advantages. Therefore, we must choose a suitable process for printing production according to the actual situation of the factory and the characteristics of the product. Only in this way can we reduce the printing production cost and improve the printing production efficiency.

clothes box

Offset printing process

The offset printing process has a multi-color group, a multifunctional web and a flat paper model. The former has a higher production speed, which can be applied to preprinted cartons with large production batches and a relatively fixed product structure. It can be used with corrugated paper after printing. Corrugated cardboard on the production line is directly mounted and bonded. The latter has a fast printing speed, which can be as large as 10,000 sheets per hour. It is suitable for printing and carton products produced in small batches. The printing specifications of the face paper can be flexible. It can also print fine corrugated cardboard directly on the flat paper model. Its overprinting accuracy is higher than the former, and its quality is relatively stable. The offset printing process has a thin ink layer, which is suitable for overprinting or overprinting of fine line plates and multi-color screen prints. It has the advantages of high screen dot resolution, rich layout printing layers, clear tone demarcation, soft tone, good printing reproduction effect, convenient and fast printing plate production, plate mounting, easy plate correction operation and lower plate production cost. Printing of color preprinted carton paper.

custom clothing box

2. Gravure process

The gravure process is also divided into web and flat paper printers, and the color box function is also available in a variety of models. The printing process has the characteristics of high printing plate resistance, high printing speed and so on. Because the gravure ink layer is thicker, the printing ink color is full and full of three-dimensional impression, the layout printing layer is rich, the texture is strong, and the printing ink color is drying faster, so it is more suitable for large area and thick ink products. The gravure process can be suitable for printing on-the-spot, spot-color line plates, and fine screen printing plates. Compared with offset printing, flexo printing, or screen printing, this process is the least likely to produce printing color differences. The quality of printed products in cartons is The most stable and best. Since the gravure printing plate is made of steel roller material through electroplating, electric engraving and other processing processes, the plate making process is relatively complicated, the plate making materials and costs are also expensive, and the plate changing operation is also cumbersome, so it is especially suitable for batches. Larger pre-printed carton printing can reduce production costs better.

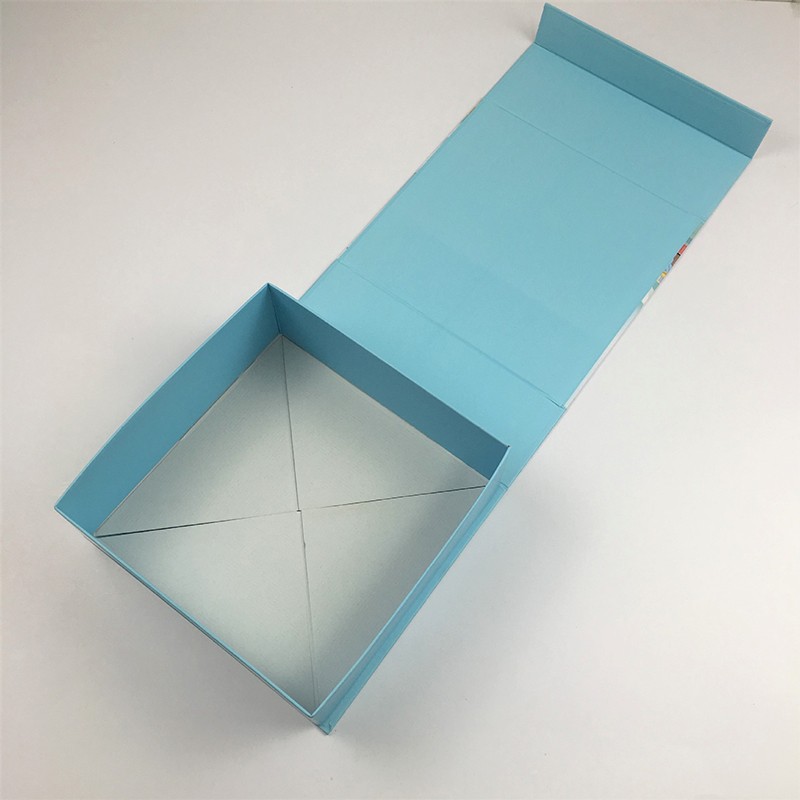

custom magnetic box

3. Flexographic printing process

The flexographic printing process is also divided into web and flat paper multi-color printing presses. Among them, flat paper printing presses have pre-printed models for printing on top paper, and direct printing on corrugated cardboard, and can complete slitting, Creased, slotted units. The flexographic printing process is compatible with the advantages of letterpress, lithography, and gravure printing processes. Because the printing plate is flexible, the printing pressure is much lighter than other processes, with lighter printing pressure, thick printing ink, clear print, and printing plate resistance. The main feature of high rate. This process can print both cardboard with good surface gloss and cardboard with rough surface; it can print non-absorbent materials and cardboard with strong absorption; it can print both thin and thick paper; It is suitable for printing fine anilox plate and line plate, but also suitable for printing line plate or solid plate of spot color. Flexographic printing plates are divided into rubber plates and resin plates. The main materials of rubber plates are natural rubber and synthetic rubber. There are three types of plate making: hand engraving, laser engraving and casting. When using a rubber plate, it should pay attention to its printability, such as considering the ink's ink compatibility, ink transfer, covering power and reproducibility, using water-based ink printing, using natural rubber plates than synthetic rubber The material is better.

t shirt box

Butyl rubber plates are more suitable for solvent-based inks. When using nitrile rubber plates, try to avoid using solvent-based inks to prevent printing plates from being damaged by solvent corrosion. The rubber plate also has the disadvantages of being easily deformed and cracked, so it is not suitable for printing fine products. The photosensitive resin plate making process is very simple, and its plate making speed is much faster than hand-engraved and cast rubber plates. The plate loading operation is convenient. The printing plate has good ink transfer performance and stable printing quality. This plate has good latitude, can reproduce finer highlight dot levels, can reproduce more than 2% of the dots, and print 150-line anilox plates. The solid resin plate has a much smaller expansion ratio than the rubber plate and the liquid resin plate, so it is more suitable for making multi-color overprint and line plates. However, the price of the solid resin plate is relatively expensive, and the production cost is relatively high. Therefore, it is more suitable for printing bulk packaging products.