How To Deal With Color Box Burst Caused By Material Quality Problems

How To Deal With Color Box Burst Caused By Material Quality Problems

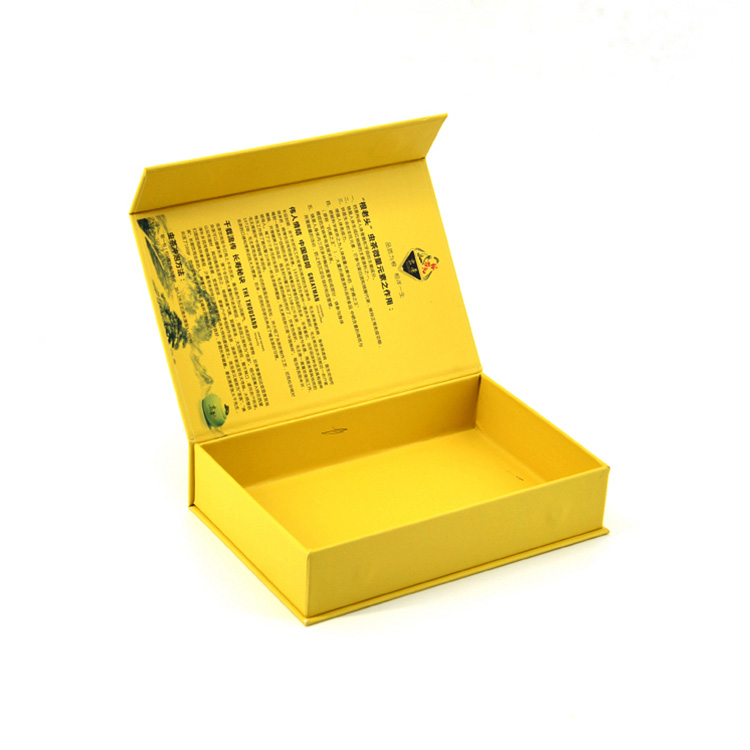

cardboard packaging boxes

1 The water content of the paper is too low, and the paper becomes brittle. This phenomenon occurs more frequently in winter. Because the weather is dry and cold in winter and the relative humidity in the air is low, this will directly affect the moisture content of the cardboard, causing the cardboard to break behind the pressure line. Generally, the water content of the base paper is controlled at the upper limit (8%).

custom cardboard box

2 Paper coating material Biaxially oriented polypropylene film has fine notches, which leads to a reduction in tensile strength. Film coating is a relatively common paper surface treatment method. The main material is BOPP film. If the BOPP film is damaged before die cutting, the BOPP film will not be forced to break when bent after die cutting. Bursts of film occur only in the film layer. When the force point extends in the burst direction, the paper on the bottom layer does not burst. This means that paper is not related to paper. If the film is not cracked, the paper has nothing to do with the film.

cardboard box for packing

3 The paper is wrong. In the die-cutting process, if the indented steel wire and the paper fiber are perpendicular to each other, and the paper fiber is damaged in the radial direction, the dark lines are easily bent, forming well, and the angle is small; if the indented steel wire is parallel to the paper fiber direction, the paper is not in the transverse direction. If it is damaged, the dark line is not easily bent, and the shape is round and the angle is large, which is easy for the outer layer of the paper to crack. This orientation of the paper has almost no effect on the die-cutting of single-sheet products, but the formation is not good, but it is not easy to disconnect, but it has a greater impact on card products. If it is not handled well, it will not form. Well, it is easy to explode, mainly because the dark lines parallel to the paper line burst at different positions, and the other direction does not explode.

3 The paper is wrong. In the die-cutting process, if the indented steel wire and the paper fiber are perpendicular to each other, and the paper fiber is damaged in the radial direction, the dark lines are easily bent, forming well, and the angle is small; if the indented steel wire is parallel to the paper fiber direction, the paper is not in the transverse direction. If it is damaged, the dark line is not easily bent, and the shape is round and the angle is large, which is easy for the outer layer of the paper to crack. This orientation of the paper has almost no effect on the die-cutting of single-sheet products, but the formation is not good, but it is not easy to disconnect, but it has a greater impact on card products. If it is not handled well, it will not form. Well, it is easy to explode, mainly because the dark lines parallel to the paper line burst at different positions, and the other direction does not explode.

corrugate cardboard box

4 Corrugated configuration is too high. The rupture strength and lateral ring compressive strength of the base paper are one of the influencing factors. If the folding resistance of the paper is too low, it may easily cause bursting.

4 Corrugated configuration is too high. The rupture strength and lateral ring compressive strength of the base paper are one of the influencing factors. If the folding resistance of the paper is too low, it may easily cause bursting.

black cardboard boxes

5 The mold usage time is too long. During the die-cutting process, the die-cutting machine will loosen after a long period of use, which will cause the crimping knife to rebound during the die-cutting process and cause the cardboard press line to break. Due to the long-term use of the rubber pad, the pressure pad is uneven due to the unevenness of the rubber pad.